The installation of electromechanical equipment aims to meet daily operational needs, and the process is relatively complex and projects are often large-scale. Therefore, during equipment installation, there are strict requirements for quality to avoid problems that may arise due to insufficient quality control after the completion of installation and acceptance.

The application scope of electromechanical equipment installation projects is usually broad, and the construction procedures vary depending on the equipment. Improving the quality of electromechanical equipment installation can to some extent reduce the cost of construction projects and provide assurance for the daily use of the delivered project.

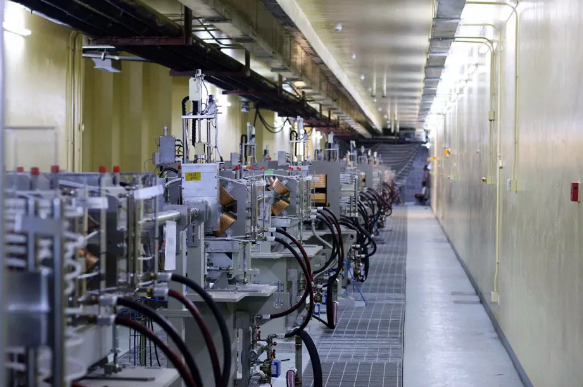

Introduction to Mechanical and Electrical Equipment Installation

The installation of electromechanical equipment mainly focuses on the installation and management of electrical equipment in construction projects. Generally, the scope of electromechanical equipment installation is extensive. The construction activities mainly include procurement, installation, commissioning, and acceptance. Moreover, electromechanical equipment installation projects are usually large in scale, so quality control of every detail during the installation process is crucial. If there is a quality issue at any point, it can potentially impact the overall quality of the entire project.

In life, large-scale projects have higher requirements for the installation of electromechanical equipment. Throughout the entire process, from bidding to construction completion, the economic benefits are continuously increasing. Naturally, the requirements for quality are also getting higher. In order to ensure the safe operation of electromechanical equipment after installation, it is important to minimize the operational risks. During equipment installation, it is crucial to effectively control every key point to minimize losses.

Control work before installation

During the preliminary stage of installation, the installation personnel need to conduct a preliminary planning for the entire project, including the scheme, design, and construction drawings, in order to prepare for the equipment installation.

1. Developing a scheme

During the preliminary stage, the installation unit needs to carefully inspect and study the construction drawings to ensure that the entire design concept and scheme (including the schedule) are reasonable. They should also understand and master new materials, construction techniques, key nodes, and processes during the installation.

After fully understanding the content of the design construction drawings, the installation unit should arrange and plan the corresponding construction steps based on their specific requirements and the characteristics of the construction site. By doing so, they can develop a construction scheme to ensure the quality of the installation of mechanical and electrical equipment.

2. Schedule

It is important to have a backup plan for the schedule of construction progress in order to deal with any unexpected situations that may arise during construction.

3. Equipment procurement

Proper arrangements and solutions should be made prior to installation, including the procurement of equipment, quality control of the equipment itself, and addressing any relevant issues regarding equipment performance.

4. Project Disclosure

The entire installation plan of the equipment is developed from a global perspective, taking into account all aspects of the construction process and considering the allocation of all resources. A detailed construction plan is formulated, along with project analysis and scheduling details.

For specific details of the project, key milestones, technologies, and important content related to project design, it is important to coordinate with the technical lead. Clear communication and instructions should be provided to the construction team on site, addressing any precautions and standard requirements for the construction process.

In general, the pre-installation control work for mechanical and electrical equipment is to make sufficient preparations for the entire installation project, including technical aspects, engineering, site management, and personnel allocation. It is important to address all the detailed issues and ensure that all problems during the installation process are within a manageable range.

Key points of control during the process

During the installation period of mechanical and electrical equipment, the quality of the installation directly affects the final operation and usability of the equipment because each detail of the installation process is interconnected. If there is a slow progress in any stage of the installation, it will impact the overall installation progress.

Therefore, during the installation period, the quality monitoring of the installation works is the most important quality control point in the whole equipment installation process, for the work of quality supervision, there must be a perfect management system:

1. Equipment Mobilization and Acceptance

(1) Mobilization plan:

The timing of equipment entering the construction site should be pre-knowledgeable and planned, as early or late arrival can have adverse effects on the equipment. The construction site may not be conducive to equipment storage, and if the equipment remains idle for a long time, it may become damp or damaged. Therefore, it is necessary to schedule the entry of mechanical and electrical equipment into the construction site based on the construction progress. This ensures that the overall performance of the equipment is not compromised and does not affect the progress of the construction.

(2) Equipment verification:

For the receiving and acceptance of mechanical and electrical equipment, it is important to confirm the consistency in quantity and condition with the delivery and receipt documents;

(3) Unpacking acceptance:

Detailed inspections should be conducted on the equipment's model and technical specifications to ensure that all equipment complies with relevant national standards.

2. Design drawings are the foundation

The installation design drawings serve as a crucial foundation for the installation process. They are used to coordinate the overall project and manage the details according to the design requirements. It is essential to have a comprehensive plan that encompasses installation procedures, technical construction methods, personnel allocation, and the construction environment.

3. Construction standards and acceptance

Strict control over the quality of the construction project must be carried out in accordance with relevant national standards. The final acceptance should be conducted based on clear legal provisions to ensure the safety of equipment operation.

During the installation process, it is important to carefully perform equipment acceptance procedures to ensure that the installation quality of each component meets the standards.

4. Emphasizing the supervision of construction techniques

Emphasizing the supervision of construction techniques is crucial because substandard quality is the most detrimental factor to the overall outcome. Therefore, installation units should carry out construction activities in accordance with specific construction processes, techniques, and conditions. After completing each procedure, the specific data and results of the progress should be promptly handed over to the on-site management personnel to ensure the accuracy of the construction and overall progress. The next construction procedure can only be carried out after being confirmed by the relevant responsible person. All inspection tools related to construction must be effective and meet the standards.

5. Process supervision

The construction unit should also have a self-inspection process for the equipment installation project, including supervision by third-party units, recognition by design units, and verification by the construction unit. The on-site construction supervisor should be responsible for the entire process of mechanical and electrical equipment installation and supervise the progress and quality of on-site installation.

In general, the control and management of mechanical and electrical equipment installation is based on a series of details such as technology, engineering, site, and personnel allocation, aiming to improve project quality and reduce project risks.