FAST, or the Five Hundred Metre Aperture Spherical Telescope, is one of nine national scientific and technological infrastructures designated by the National Leading Group of Science and Education. It utilizes both the original design of Chinese scientists and the unique topographical conditions of karst depressions in southern Guizhou, China. The construction of a radio telescope with high sensitivity, which spans about 30 football fields, ensures world-class equipment for the next 20 to 30 years.

Let us explore the world's largest-calibre radio telescope, the FAST, and uncover its installation secrets.

01 Site selection

Since 1994, the project name for the new generation of large radio telescopes has progressed through various stages including LT, KARST, FAST/SKA, and FAST, with each phase having specific demands for the station location. While the scientific and technical requirements for the station site have become clearer, the scale and morphology requirements for the depressions have become more specific. To aid in the digitisation of the topographic elevation of the 24 depressions, we have developed a GIS for Dawotou, Taiduo, and Shangjiachong. This helps determine the excavation volume of earth from the sphere by analysing typical profiles and fitting the excavated volume. On the basis of digitising the terrain elevation, analysing the typical profile, and fitting the excavated earth volume in the 24 depressions, a geographic information system has been developed for fitting the excavated earth volume of the FAST project in Dawopai, Taido and Shangjiachong. The excavated earth volume can be calculated by determining the radius of the sphere, the radius of the opening, the elevation at the bottom of the sphere crown, and the planar coordinates of the sphere centre. Technical abbreviations such as FAST have been explained when first mentioned. It was determined that Dawo Cotai is the optimum location for constructing a 500-metre-calibre spherical radio telescope.

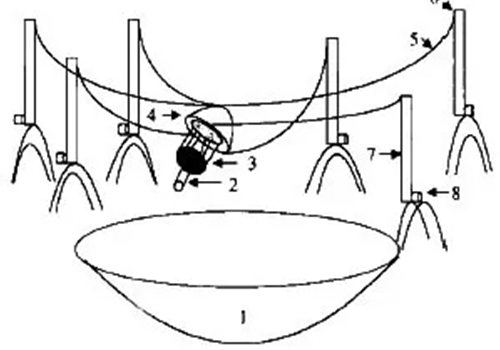

The figure displayed above illustrates the inventive design of FAST, featuring the following components: 1-Major reflecting surface, 2-Feeder, 3-Stewart platform, 4-Feeder module, 5-Suspension cable, 6-Pulley, 7-Support tower, 8-Winding wheel and servo system.

02 Installation

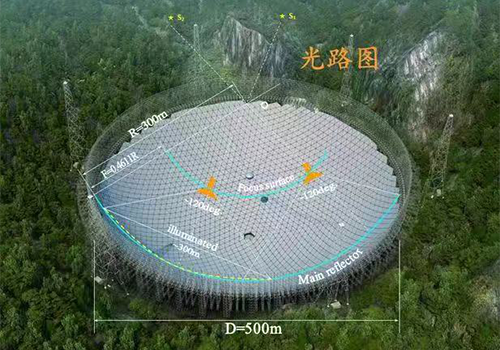

The performance results of FAST are presented below: Located at longitude 106°E and latitude 26°N with

an altitude of 1000 metres, the reflecting surface aperture measures 500 m with a 120° crown opening and a spherical surface radius of curvature of 300 m.

Effective illumination aperture: 300m.

Maximum zenith angle: 50°. The operating frequency ranges from 0.3 to 1.72 GHz, 2.15 to 2.35 GHz, 2.8 to 3.3 GHz, and 4.5 to 5.1 GHz, with an additional range of (5.7 to 6.7 GHz and 8.0 to 8.8 GHz).

Pointing tracking accuracy is 4 arc seconds.

Hoisting: The FAS reflective panels were lifted on 2 August 2015 to a height of 60 metres. Each triangular panel has an area of over 50 square metres and weighs up to 900 pounds per piece despite being made of aluminium alloy. A total of 4450 panels were installed.

Splicing: To appreciate the expansiveness of the starry sky in a neutral manner, it is crucial to accurately determine the boundaries of the sub-units in the assembled panels. Researchers have developed a positioning jig that locates the horizontal position and axial height of each panel accurately. This jig ensures that the intersection of every equilateral triangle remains precise at 0.1-0.15mm. During every step of the installation of FAST, precision is crucial, and there is no room for error.

On 25 September 2016, the official opening of FAST, the world's largest single-calibre radio telescope, took place. The attraction where the telescope is located was put into trial operation with the public on 26 September of the same year. Within the scenic spot, visitors can find the FAST Observatory, Astronomy Experience Museum and Cultural Park, which offer a unique experience.

The completion of FAST has special value in the field of astronomy, as well as important significance in the field of equipment installation engineering.